April 17, 2011 - Believe it or not, I continue to make forward progress. I still haven't mounted the motor/transaxle but with good reason. For this blog entry, I have started wiring the low-voltage circuits in the engine compartment affectionately known as the "hell-hole".

Now, the reason I haven't mounted the motor/transaxle assembly into the engine compartment is that the original throttle cable I purchased from Pelican Parts became defective last weekend. From what I understand, these Gem cables are notorius for breaking. So I ordered another Gem and a higher-priced Terri cable from Pelican Parts. Pelican Parts is an awesome supplier. They keep you well-informed during the entire order processing flow via e-mail, and ship the merchandise ASAP.

So I received the new cables mid last week and immediately installed the Terri cable which I really like over the Gem cable. I hooked it up to the custom pot box from Mark Hazen at EVHelp.com (it came with the controller I purchased from him) but to my dismay, when the accelerator is pushed all the way to the floor, the pot box lever only defleected about 1/4 way. Mark's pot box doesn't start registering the pot changes until the final quarter or third of the defleection. Hmmm, this won't do. Here's a pic of the pot box enclosed in a nice aluminum box I purchased from MCM Electronics for $15.

Notice the aluminum extension on the left. I needed to extend the length of the enclosure as the cable was too long and no effective way to shorten it. Soooo, I've ordered a standard Curtis PB-6 from Electric Vehicles of Washington for $80, the cheapeast I could find without getting a knock-off from China. It looks the the deflection of a common Curtis PB-6 is about half or less than that of Mark's pot box.

Next up is the installation of the emergency breaker. I got this 120VDC Airpax breaker brand new off of eBay for a very nice price. It fits very nicely onto the firewall. Obviously, I haven't wired it up to the 2/0 cables yet but that part is coming soon enough. I may go ahead and start the 2/0 cabling before I mount the motor/transaxle assembly. It will be that much more difficult to do so after its mounted. Here's a closeup of the breaker. The wire attached to the breaker switch is the heater flap cable which is connected to a lever located very close to the stick shift. Easily accessible if motor ever attempts to runaway for whatever reason.

And another shot showing the breaker in geographical relation to the controller.

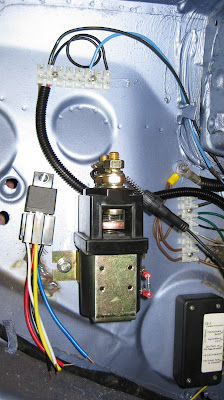

At last, I spent a lot of time on a mechanic's crawler getting in and out the the hellhole. What a PITA. But I was able to get most of the low-voltage wiring completed. I just need to hookup less than a dozen wires or so to complete the task. You can also see the fuse block at the bottom left that will contain a Ferraz Shawmut fast-acting amp-trap fuse. I haven't figured out where to mount it yet but am leaning toward the shelf that is at a 45 degree angle to where it currently sits. The negative end of the front pack will connect to one end of the fuse and the positive end of the rear pack will connect to the other end.

In this picture you can see the relay (left of the main contactor) I've added for the Motor Temp switch that comes with the Warp9 and is normally closed but opens when over temp is reached. I'm using the relay to complete the circuit to ground to the Oil Pressure indicator (red) on the Fuel Gauge. It hasn't been wired up yet.

Here's a closeup of the control box from EVHelp which has 3 relays built into it to prevent an improper startup sequence, mainly, 1) parking break off, 2) foot off accelerator, and 3) foot on brake.

Here's a closeup of terminal block #2. The in-line fuse that is resting on one of the contactor high-voltage terminals comes from the control box and will be wired up to pack side with a ring connector.